- Home

- Products

- Concrete Mixing Plant

- Popular Product

- Stationary Concrete Batching Plant

Stationary Concrete Batching Plant

As a mature manufacturer of stationary concrete batching plant, HAMAC designed this series stationary concrete batching plant which is suitable for commercial concrete sale and own projects. It is equipped famous brand components such as pneumatic cylinders, vibrators, air compressor, SICOMA concrete mixer and motors etc.

TAG: Concrete batch plantConcrete batch plant near meMobile concrete batch plant

What is concrete batching plant for sale?

A Stationary Concrete Batching Plant is a complete production line designed for the production of ready mix concrete. This plant efficiently handles the weighing of aggregates, sand, cement, fly ash, additives, and water-reducing admixtures, all of which are crucial components in the concrete mixing process. The entire procedure is seamlessly controlled by computer software, ensuring precision and consistency. Once the concrete is mixed, it can be transported to the job site using a concrete transit mixer. In some cases, it can also be directly fed into a concrete pump machine for easy and efficient placement.

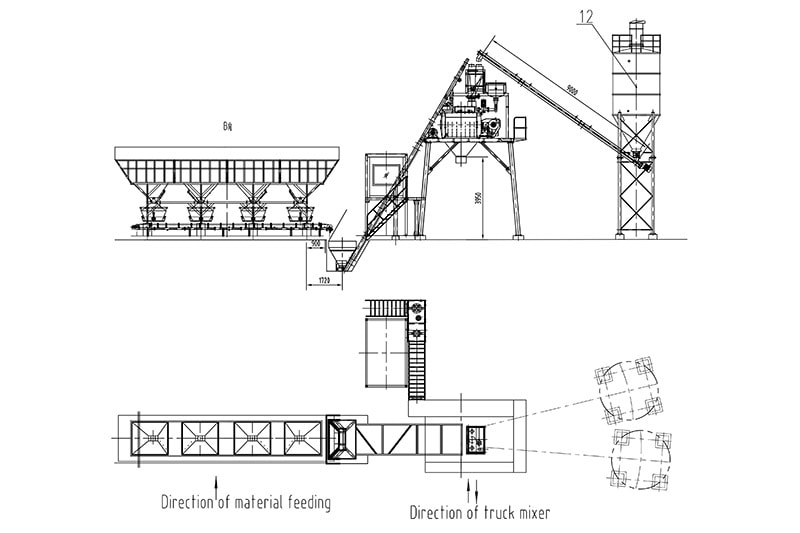

The following two pictures are the overall layout of two typical concrete batch plants for sale:

The main components of ready mix concrete plant

For a complete concrete plant for sale, it contains the following parts;

1.Aggregate batching machine, it will weigh the weight of different sizes aggregates, sand according to the formula which is input into the software system, and then feed the material into the concrete mixer;

2.Belt conveyor or skip hoist bucket, after the sand and gravel is measured in the aggregate batcher machine, it is conveyed to the mixer by the belt conveyor or skip hoist bucket;

3.Central mixer, it is an equipment that fully mixes the raw materials of cement, sand, gravel and water admixtures to produce concrete. It is mainly composed of motor, reducer, mixing tank and discharging mechanism. The concrete plants for sale is mainly equipped with twin-shaft concrete mixer;

4.Concrete batching plant cement silo, it is used to storage the cement and fly ash;

5.Weighing system for cement, water and additive, the load cells are equipped to each weighing hopper for different materials;

6.Additive supplying system, for some projects, the additive such as water reducing agent in concrete should be used to produce water reducer concrete, accelerates the setting of concrete. There is a system to supply additive to the water tank;

7.Water supply system, the water pump transfer the water from ground to the water weighing hopper above the concrete mixer;

8.Pneumatic system, an air compressor is equipped to provide the air to open and close the cylinder, butterfly valves etc;

9.Electrical cabinet and software control system, the formula will be enter into the system, so that all the procedures can work automatically;

Concrete batch plant layout:

In order to explain clearly how the concrete batch plant works, we prepare this concrete batch plant layout, please check it.

Belt conveyor type concrete batch plant VS Skip hoist type concrete batch plant

As we all know, there are generally two feeding methods for concrete batching plants for sale; one is hopper feeding, skid hoist type; the other is belt conveyor feeding. So, when customers buy a concrete batch plant for sale, how should they choose the feeding method of the concrete plant for sale?

Let us see the difference between these two types batch plant for sale as blow:

The three characteristics of the skip hoist type concrete mixing plant for sale are:

One is that it occupies a small area and is suitable for use in narrow places with limited space; the other is that it is very convenient to be installed and relocated; The third is that this concrete plan price is cheaper, so it is also widely used in high-speed railway, highway, and urban commercial ready mix plant for sale in domestic market or overseas market. It is usually considered as small ready mix concrete plant.

The characteristics of the belt conveyor type concrete mixing plant for sale are:

The belt conveyor feeding method adopts the principle of conveyor belt, which is more complicated in design than hopper feeding, but has high feeding and transportation efficiency, can quickly complete large-scale operation requirements, and improve production efficiency by more than 20%; The belt conveyor feeding has a short production cycle and a big capacity, which is suitable for commercial concrete atching plants;

Disadvantages: large occupation area, high electricity consumption, and large investment in concrete batching plant for sale.

Based on the above information, the client can make the decision to choose the suitable concrete batching plant to build the concrete factory for sale.

Wet batch concrete plant VS dry batch concrete plant

There are two types concrete batch plant for sale in the market. One is wet batch concrete plant, another one is dry batch concrete plant.

Wet batch concrete plant is a concrete batching plant with central concrete mixer to mix the aggregates, sand, cement, water and additive to produce the ready mix concrete for sale. It is the most popular central mix concrete plant in the market. After mixing, the ready mix concrete will be transported to the job site by the truck mixer.

Dry batch concrete plant is a dry concrete batching plant without central concrete mixer, this is the most important difference compared with wet batch concrete plant. It is dry mix. All the aggregates, sand, cement and water will be discharged into the concrete transit mixer without mixing. The concrete will be mixed in the drum mixer on the way to working site.

Additional equipment required for CBP

When you want to invest in a commercial ready mix concrete batch plant for sale, it is important to consider the added services that can be offered to make the end user comfortable, solve their potential problems, and make the business more efficient. What will other equipment be like?

1.Mixer truck is a device used to transfer ready mix concrete from the batching plant to the working site. At least, you need to buy a concrete mixer truck to help the client transit the concrete. The size of the concrete batching plant will determine the amount of concrete that can be produced.

2.Truck-mounted concrete boom pump, some clients will buy the concrete for their high building, but they don’t have the means to pump it. You can provide a pumping service for your project together with concrete selling. The increased possibility for the end user to choose the one who can provide the specific pumping machine service will make it more likely that the end user will choose the one who can provide the best service.

3.Concrete trailer pump for sale, which is suitable for long term projects, just put this concrete pump for sale near to the building, and pouring the ready mixed concrete according to requirement. Then it can pump the concrete to the high rise building.

According to our experience, most of the ready mix concrete supplier provide the above service. You can add the cost into the concrete price for sale.

Why choose HAMAC concrete batch plant?

HAMAC concrete batch plant adopts famous brand parts to make the mixing plant works stable and reliable.

- 1.Pneumatic cylinder, from Japan SMC;

- 2.Vibrators, from Italy WAM;

- 3.Butterfly valves, from Italy WAM;

- 4.Air compressor, water pumps, cables and electrical components are from top-class suppliers;

- 5.Separate gearbox, motor and drum for belt conveyors, it will be more convenient for the client to maintain it;

- 6.All the machines are above ground, more convenient for maintain;

- 7.Bolted type cement silo, to save the shipping cost. All the accessories for cement silos are from Italy WAM;

Concrete batching plant manufacturers

When it comes to Stationary Concrete Batching Plants, there are several professional concrete batching plant manufacturers in China. HAMAC is one of the notable names in this domain, specializing in the production of top-quality concrete batching plants and concrete pumping plants. Our machines have earned the prestigious EU CE certification and are trusted in developed countries, including Europe and the United States. We offer a wide range of products, encompassing stationary concrete batching plants, mobile concrete batching plants, dry-type concrete batching plants, and more. As your ideal supplier for various concrete batching plant needs, we are committed to delivering excellence in construction equipment.

Stationary Concrete Batching Plant Goods Delivery

Based on good quality and decades of experience, the Stationary Concrete Batching Plant which is manufactured by HAMAC was exported to different countries. The Stationary Concrete Batching Plant will be packed and loaded in our factory, and then be shipped to our clients safe and sound.

Stationary Concrete Batching Plant Specification

| Technical data | Model | ||||||

| HZS60 | HZN60 | HZS90 | HZN90 | HZS120 | HZS180(150) | HZS240(200) | |

| Theoretical capacity(m³/h) | 60 | 60 | 90 | 90 | 120 | 180(150) | 240(200) |

| Mixer model | JS1000 | MP1000 | JS1500 | MP1500 | JS2000 | JS3000 | JS4000 |

| Batching system | PLD1600 | PLD1800 | PLD2400 | PLD2400 | PLD3200 | PLD4800 | PLD6400 |

| Discharging height (mm) | 4100 | 4840 | 4100 | 4100 | 4100 | 4100 | 4100 |

| Maximum aggregates size(mm) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) | 60(80) |

| automatic Cycle time(s) | 60 | 60 | 60 | 60 | 60 | 60(72) | 60(72) |

| Weighing Precision of Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% | ±2% |

| Weighing Precision of Cement | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Water | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Weighing Precision of Additive | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% | ±1% |

| Total power(KW) | 106 | 114 | 145 | 145 | 175 | 215 | 295 |